Insulation system with real bricklips

Brickslips made from pure clay - intelligently combined with high quality insulation plus carrier system.

Please click for download brochure: [hippo-faicon name="file-pdf-o" size="16" color="" class=""] Download

There are many diverse exterior wall possibilities for combining Celina brick-slips with thermal insulation systems

According to state and strength of the insulation, different thermal insulation standards can be reached. Some examples from current building practice now follow:

Traditional wall construction with brick slips and corners

In these "conventional" thermal insulation systems, the brick-slips are applied onto insulating panels. However, these must firstly be reinforced with a special membrane or mesh, then the brick-slips are fixed with adhesive and pointed. A tight cord placed horizontally helps in the correct alignment of the brick-slips.

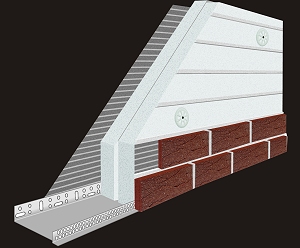

The modern wall construction with thermal insulation system and carrier system

The modern wall construction with a combined thermal insulation system and carrier-system suit provides an overall even installation. One saves a complete process because here the installation of a special membrane or mesh is superfluous. The panels are fixed directly on the old facade with additional plug fixings. Especially for the retrospective insulation of older properties, these high-value systems are ideal. The panels are interlocked all around by means of tongue and groove so that no cold bridges emerge.

The Renowall Insulation system | EPS - System

The Renowall Insulation system | EPS - System

These modern carrier systems come in standard thicknesses from 40 up to 300mm and support different brick slip formats. To avoid heat bridges (cold spots) the panel should be unconditionally equipped with interlocking tongue-and-groove rebates.

For more information please click www.renowall.de

EPS insulation panel with carrier system

EPS insulation panel with carrier system

In this thermal insulation system with carrier system, the warmth insulating panel consists of Polystyrene foam (EPS). Also here the brick slips are fixed directly onto the backer panel with adhesive, without an additional membrane or mesh. The heavy duty plugs "disappear" in the recessed gaps of the panel. The adhesive is applied with a toothed trowel and are brick-slips are pressed into the adhesive bed. The façade is then conventionally pointed with a suitable mortar.

XPS insulation panel with carrier system

XPS insulation panel with carrier system

Thermal insulation system with carrier system and plug fixings. Based on an extruded hard foam panel (XPS). This panel is suitable where good water stability and pressure stability are demanded even to the parts of the facade that stand in direct connection with the soil around perimeter areas.

Why to choose a thermal insulation system ?

- Environment

- Energy

- Heating cost reduction

- Room benefit

- Living improvement

The entire world speaks about the “greenhouse effect” and an overproduction of CO2 from the burning of fossilized energy resources. If you plan to renew or brighten up the outside façade of your building, should think you about additional warmth protection too. Scaffolding costs occur anyway and the additional costs for the insulation will, through savings in energy consumption, quickly pay for itself.

Delivered incidentally is also another contribution to environmental protection because of new low energy standards for new buildings. It should therefore be considered from the start how to achieve the optimal values. If a thermal insulation system is selected, there are space gains because the overall wall thickness can be reduced. Thermal insulation systems provide a more uniform comfortable room climate which can bring added benefits of well-being. Mold development and draughts are prevented.